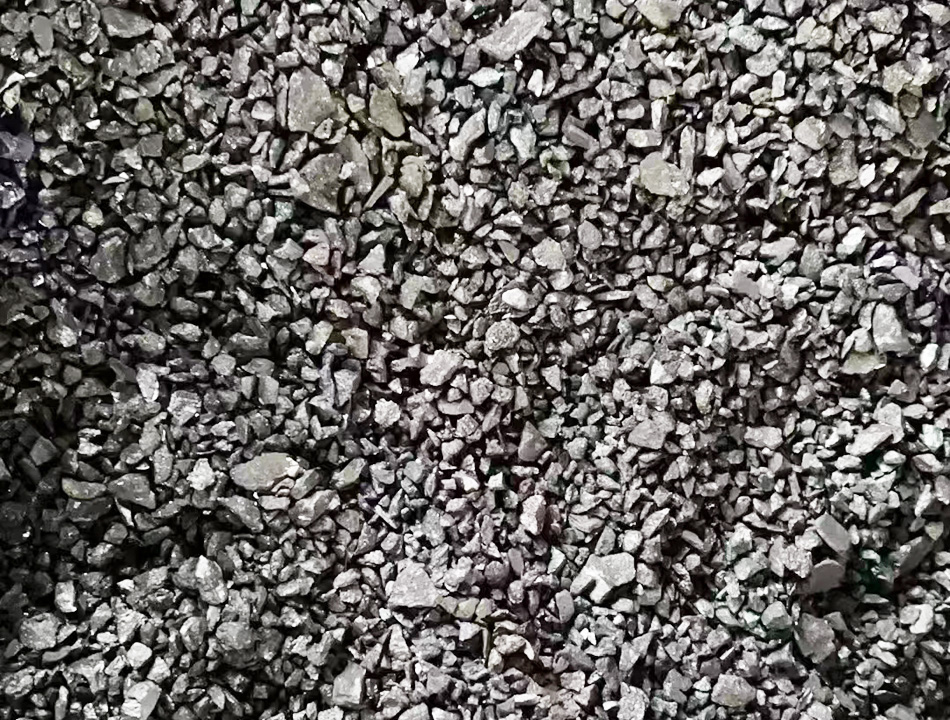

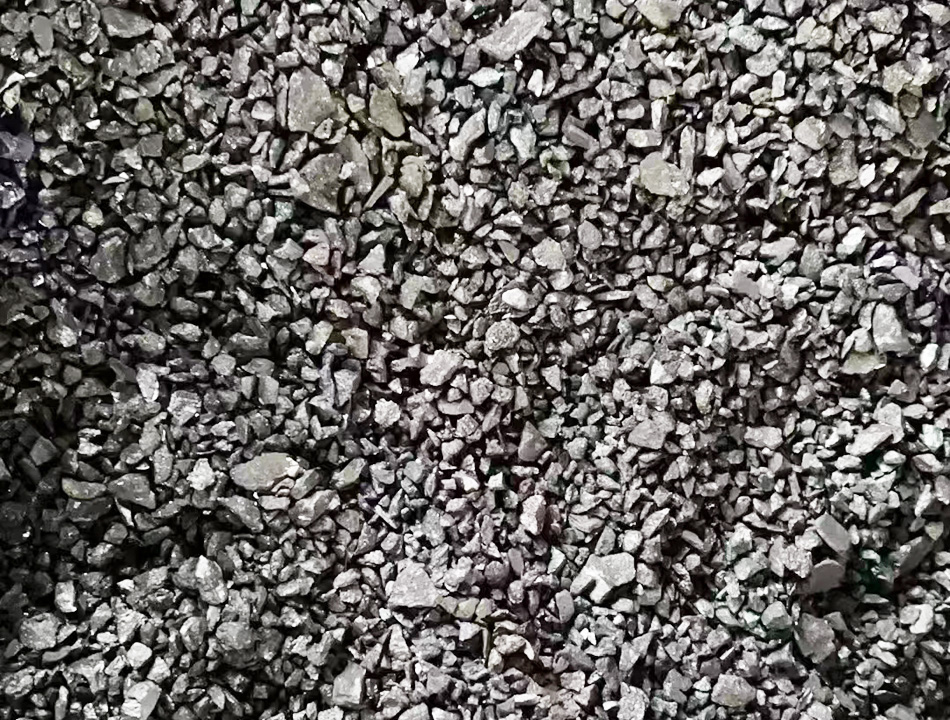

Ferro silicon is widely used as deoxidizer and alloy additive in steel making, and also can be used as an inoculant and nodulizer for cast iron. Ferro silicon powder or atomized ferro silicon powder can be used as coating for welding rod production.

Particle Size: 0-1mm, 1-3mm, 3-8mm, 10-50mm, 10-70mm, 10-100mm, 50-150mm, etc.

Package: 1Mton big bag.

Ferro silicon is used as a deoxidizer in steel making production. When the silicon in the ferro silicon combines with oxygen, a large amount of heat is released due to the formation of SiO2, which is also beneficial to increase the temperature of the molten steel while deoxidizing.

Ferro silicon can also be used as alloying element additives, widely used in low-alloy structural steel, spring steel, bearing steel, heat-resistant steel and electrical silicon steel. In the steel making industry, about 3-5kg of 75% ferro silicon is consumed for every ton of steel produced.

|

Type |

Content of Elements |

|||||||

|

% Si |

% Al |

% Ca |

% Mn |

% Cr |

% P |

% S |

% C |

|

|

FeSi75Al0.5-A |

74.0-80.0 |

0.5 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al0.5-B |

72.0-80.0 |

0.5 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al1.0-A |

74.0-80.0 |

1.0 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al1.0-B |

72.0-80.0 |

1.0 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al1.5-A |

74.0-80.0 |

1.5 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al1.5-B |

72.0-80.0 |

1.5 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al2.0-A |

74.0-80.0 |

2.0 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al2.0-B |

74.0-80.0 |

2.0 |

1.0 |

0.4 |

0.3 |

0.04 |

0.02 |

0.1 |

|

FeSi75Al2.0-C |

72.0-80.0 |

2.0 |

|

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75-A |

74.0-80.0 |

|

|

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75-B |

74.0-80.0 |

|

|

0.4 |

0.3 |

0.04 |

0.02 |

0.1 |

|

FeSi75-C |

72.0-80.0 |

|

|

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi65 |

65.0-72.0 |

|

|

0.6 |

0.5 |

0.04 |

0.02 |

|

|

FeSi45 |

40.0-47.0 |

|

|

0.7 |

0.5 |

0.04 |

0.02 |

|

If you need our products please write down any questions, we will reply as soon as possible.

High carbon silicon is a new type of alloy with stable and reliable performance used in converter steel making, which can replace ferro silicon, silicon carbide and carburizers.

Alloys cored wire is a special form deoxidizer for the steel making industry. It is a core wire made of various specific alloying element powders or grains, physically mixed in a certain proportion, and then tightly wrapped with a thin iron sheet.

Ferro silicon barium is suitable for inoculation treatment of gray cast iron or ductile iron with strict requirements on air tightness or leakage. Ferro Silicon Barium is easier to dissolve and absorb than ordinary inoculants, and can reduce the gas content in molten iron.